Sustainable Electronics Manufacturing: Innovations & Challenges

As the world continues to change at a fast rate, the electronics industry is also actively in an ever-changing era characterized by remarkable transformations. Among these transformations is the growing demand for sustainability, especially at this time when the emission of greenhouse gases continues to increase.

Today, the electronics industry is responsible for up to 4% of all greenhouse gas emissions. This calls for sustainable innovations to help reduce the environmental footprint. With innovative processing methods and material choices, the environmental impact of producing integrated circuits (ICs) and printed circuit boards (PCBs) can be reduced easily.

Some of the strategies that could be adopted include utilizing novel approaches, reusing and recycling materials, eliminating superfluous materials, and adopting low-temperature processing. The effective utilization of these approaches can significantly help in reducing the environmental footprint of the electronics industry.

A Shift to Sustainable Electronics Manufacturing

There is currently so much emphasis on sustainability today thanks to the efforts of eco-conscious investments and governmental directives. Most businesses and industries are rapidly embracing various environmental regulations to further protect our planet. Before now, compliance with these regulations was considered a burden, but it has now evolved to an opportunity everyone seeks to utilize.

In the electronics industry today, some of the smartest financial decisions to make are implementing strategies for recovery and recycling and embracing low-emission production processes. Companies and manufacturers are also rapidly positioning themselves so that they can maximize the trend of social and environmental investments.

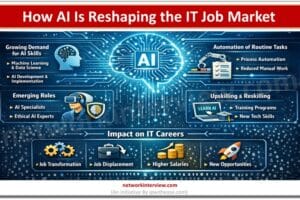

An Era of Intelligent Manufacturing

Innovation is an unstoppable force in sustainable electronics manufacturing. The integration of the Internet of Things and artificial intelligence has further helped in redefining cost-effectiveness, efficiency and waste reduction. There are also many intelligent digital manufacturing strategies that are utilized today.

These technologies streamline manufacturing processes and automate operations. With the current growing need for sustainable practices, the need for the electronic industry to eliminate practices that cause climate change cannot be overemphasized. This also includes the shift to the use of low-emission and low-toxicity chemicals.

Reducing Carbon Footprint

In an advent to shift to sustainable electronic manufacturing, there’s also a need to mitigate the industry’s carbon footprint. This need is especially for manufacturers that still make use of traditional manufacturing processes and methods. Different governments are now enacting stringent rules on emissions, which further increases public scrutiny. With that, it becomes essential for manufacturers to become accountable.

Manufacturers should switch to the use of renewable energy sources. Even though this might be initially expensive, it offers more benefits in the long run. Fortunately, the growing demand for recycled materials makes things a lot easier for manufacturers. Today, recycled materials can be utilized for other applications.

Even though product cost increases with the use of sustainable, innovative designs, we live in an era where everyone is ecologically conscious. Therefore, investing in these sustainable, innovative approaches is worthwhile.

Challenges in Sustainable Electronics Manufacturing

Even though there are so many innovations for sustainable electronics manufacturing, there are also a few challenges. There’s a need for an all-out transformation to reduce the large carbon footprint of the industry. Even though the adoption of the use of renewable energy is increasing by the day, it requires massive upfront investment, which can discourage some manufacturers.

Another challenge is that adopting efficient processes for manufacturing can cause alterations to workflows that have been in use for many years. An ongoing challenge is the need for recycled materials to meet the ever-growing demand for producing electronic components.

In addition, it’s worth noting that designing and manufacturing sustainable products increases the cost of production. This can be challenging for manufacturers, especially those that are yet to create a balance between planetary responsibility and profitability.

Sustainable Electronic Manufacturing: What the Future Holds

Despite the challenges above, there are many opportunities in sustainable electronic manufacturing. The growing demand for sustainable electrical components is a driving force among both businesses and consumers. It influences the choices they make when they buy semiconductors and other electronic components.

Before now, the concept of renewable energy didn’t make any sense, but technological advancements have changed that. There’s currently a surge in the market for recycled materials, which is promising for sustainable production.

Manufacturers are also widely accepting the use of intelligent manufacturing, which is good for the future of sustainable electronic manufacturing. This will further help revolutionize waste reduction and efficiency.

Incentives for Sustainability

Green investment initiatives and government mandates are two factors that drive sustainability in the electronics and semiconductor industries. Today, more people are consciously making choices to purchase from manufacturers that prioritize sustainability.

Manufacturers that implement processes that minimize emissions, recovery schemes, and material recycling enjoy long-term benefits. They also further reduce the cost of superfluous steps, energy consumption, and waste treatment. In addition, prioritizing sustainable practices allows companies to stay ahead, especially now that legislation and regulations are becoming more stringent.

Digitization for Sustainable Manufacturing

As mentioned earlier, there are many opportunities in sustainable electronics manufacturing. This is with respect to reducing waste, improving cost-effectiveness, and increasing efficiency. One of the key things to expect in the near future is the full integration of the Internet of Things and artificial intelligence into sustainable manufacturing processes.

Conclusion

The electronic manufacturing industry is currently at a crossroads that can influence many things. Today, the growing demand for sustainability is further influenced by the change in customer’s preferences and environmental concerns. This further influences the conventional approaches that have been used in manufacturing processes for decades.

There are also many challenges associated with sustainable manufacturing processes. However, all of these challenges are surmountable, and the main thing to understand is that the rewards are many. They include the creation of a cleaner planet and financial gains. The world is rapidly becoming ecologically conscious, which makes sustainable electronic manufacturing to be more than just a trend. It is now an important and vital moral obligation that shows great promise for the future.